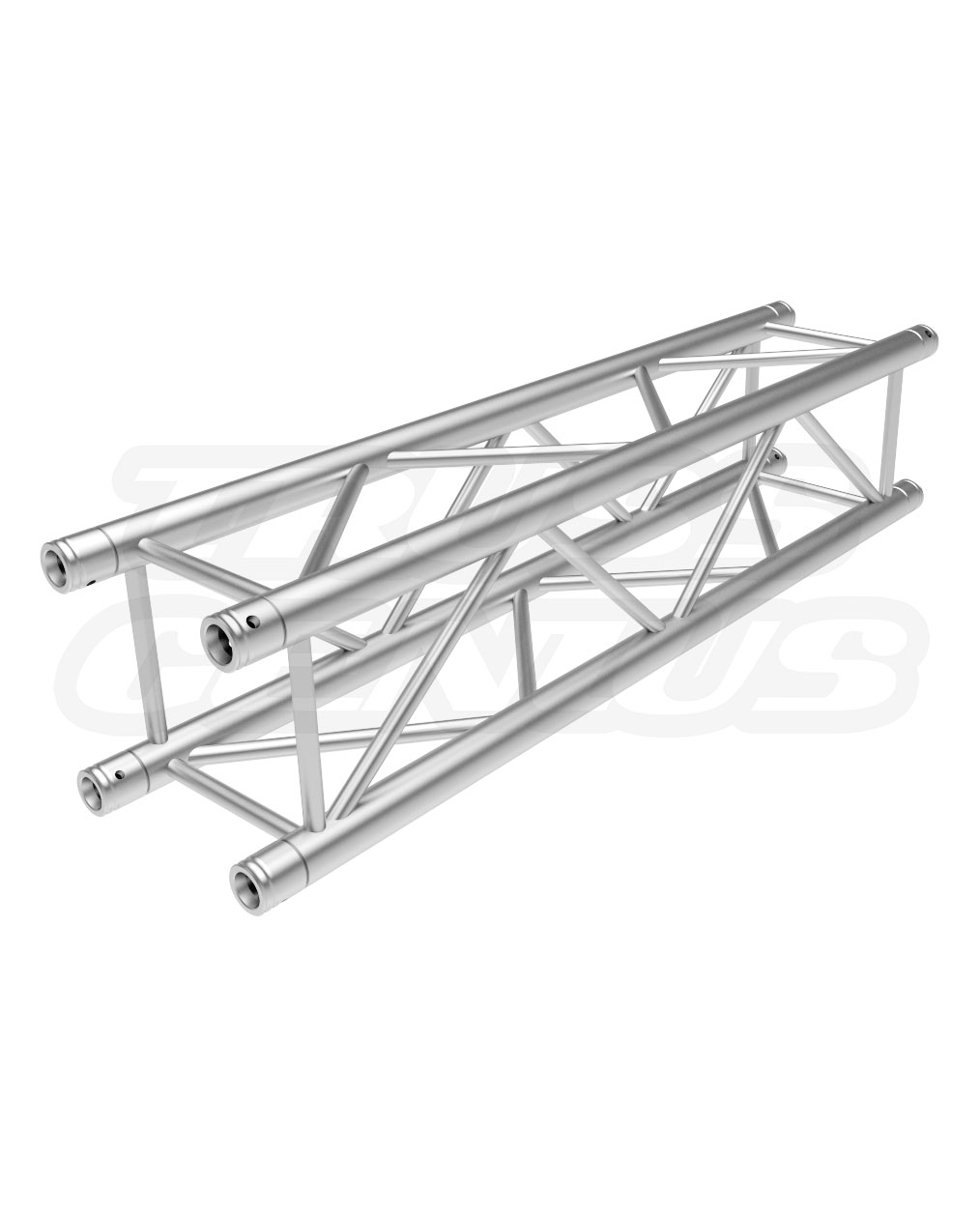

EVT290S-125 | 4.10ft (1.25m)

$314.00

EVT290S-125 | 4.10 ft (1.25 m)

Medium-Duty Square Aluminum Truss

Dimension: 4.10 ft (1.25 m) Straight Segment

Overall, Truss Width: 11.41 in (290 mm)

Main Tubing:

1.96 in (50 mm) Outer Diameter Tubing

0.078 in (2 mm) Wall Thickness

Brace Tubing:

0.78 in (20 mm) Diagonal Bracing

0.078 in (2 mm) Wall Thickness

Material: Aluminum Alloy EN AW-6082 T6

General Information:

Connecting Hardware Included

Aluminum Brush Finish

TUV Certified

Weight: 22 lb (10 kg)

Brand Name: Evolve Truss

Place of Origin: Guangzhou, China

In stock

Product Description

The EVT290S-125 Square Aluminum Truss is a perfect blend of functionality and aesthetic appeal for event productions. Offering medium-duty performance, this truss is ideal for concerts, trade shows, and various event productions. Fabricated according to TUV specifications with high-quality 6082-T6 alloy aluminum, it features a secure conical connection system for quick assembly; consisting of the conical receiver and the conical coupler, always secured together for safety, with the coupler pin and r-clip.

Quality and Durability: Made of durable, corrosion-resistant aluminum alloy with a brushed finish for a stylish look and lasting quality.

Easy Assembly: Features a simple yet secure conical connection system for quick setup, ensuring stability and safety.

Application and Use: Ideal for a wide range of applications, including lighting rigs, stage backdrops, and more.

Certified Quality: TUV certification ensures top safety and quality standards, offering peace of mind for event organizers and participants.

Choose the EVT290S-125 Square Aluminum Truss for reliable support and a professional finish in your event setups, backed by the precision engineering of Evolve Truss and supported by our specialized 50 mm (about 1.97 in) clamps, enhancing the functionality and safety of your staging projects.

Safety Note

Do not exceed the load capacity of the EVT290S-125. No loads are permitted or should be supported from the connection point of the trusses. All loads have to be distributed equally to both cords. The EVT290S-125 should be thoroughly inspected before use. In the occurrence of any damage or defect, the EVT290S-125 should not be used and must be taken out of service immediately and marked with DO NOT USE, destroyed, or recycled. Handle the truss segments with care and caution. Don’t drop them, drag them, and don’t throw truss segments on top of each other. Truss assembly should be carried out by those who are familiar with trussing. Do not attach the truss with damaged or fewer coupler connectors than required. Ensure the coupler connectors are installed correctly and that the coupler pin and cotter pins are secured. When designing and rigging truss systems, please factor in any possible transverse forces (i.e., wind load forces). Using trusses or parts from different manufacturers is not permitted and is discouraged. The purchase of this product in no way shall be conceived as authorizing or approving a specific installation or usage of the aluminum box truss. A licensed professional engineer shall review all structures, lighting plots, or other aluminum truss uses.

Shop with Confidence at Truss Genius – Your Trusted Truss Source

At Truss Genius, we are dedicated to providing our customers with the highest level of customer service and support. Our team of highly-trained and knowledgeable experts is here to assist you every step of the way. We take pride in offering exceptional service and are eager to hear from you. Contact us today via phone or email to experience our commitment firsthand.

Authorized Dealer for Major Truss Manufacturers

As a leading authority in the truss industry, Truss Genius proudly serves as an authorized dealer for all major truss manufacturers. This means we have the expertise and connections to offer you a wide range of top-quality products from renowned brands. Whether you’re looking for truss systems from industry-leading manufacturers, Truss Genius is your one-stop shop for exceptional products that meet your specific needs.

Ensuring Your Security is Our Top Priority

We understand that security is paramount when it comes to online shopping. That’s why we have implemented stringent measures to guarantee your peace of mind. Our shopping cart surpasses the latest standards and utilizes state-of-the-art “Secure Socket Layer” (SSL) technology. This ensures that all personal customer information is encrypted, providing the highest level of protection against unauthorized access.

Please Note: Prices and Offers Are Subject to Change

We believe in transparency and want to keep you informed. While we strive to provide competitive prices and attractive offers, it’s important to note that prices and offers are subject to change without prior notice. We continuously monitor the market to ensure fair and competitive pricing, so you can trust that you’re receiving the best value for your investment.

Experience the Truss Genius Difference Today

Join the countless satisfied customers who have chosen Truss Genius as their go-to truss provider. With our unwavering commitment to customer support, secure transactions, and access to an extensive range of products from leading manufacturers, we are confident in delivering a superior shopping experience. Discover the Truss Genius advantage today. Contact us now to embark on a seamless truss-buying journey with a trusted industry expert.